Unlock the Proven Approach to Eliminating Bottlenecks, Increasing Throughput, and Driving Sustainable Business Value—Fast.

Learn how organizations in high-tech manufacturing, healthcare, consumer goods and services, aerospace & defense, logistics, and more have applied this system to:

… even if you’ve tried other improvement programs that didn’t work.

Watch the video below to see how the Business Value Accelerator Program has helped organizations overcome real-world business challenges.

Unlock the Proven Approach to Eliminating Bottlenecks, Increasing Throughput, and Driving Sustainable Business Value—Fast.

Learn how organizations in high-tech manufacturing, healthcare, consumer goods and services, aerospace & defense, logistics, and more have applied this system to:

… even if you’ve tried other improvement programs that didn’t work.

Watch the video below to see how the Business Value Accelerator Program has helped organizations overcome real-world business challenges.

Client Engagements & Industry Expertise

Real-World Business Challenges

Over the course of my career, I’ve worked with Fortune 500 companies, government agencies, and private enterprises, teaching their teams how to eliminate inefficiencies, improve workflows, and scale business operations – more than 300 clients to date. While every industry has its own nuances, the challenges they face are strikingly similar—bottlenecks, misalignment, and wasted resources that hinder growth and profitability. Here’s a look at some of the most critical business problems I’ve helped client teams solve across multiple industries.

High-Tech Manufacturing: Scaling for Production Without Failure

One of my earliest and most critical engagements was with a Top Secret, Department of Defense

project transitioning from prototype to full-scale production.

The problem? It was doomed to fail.

After speaking with the fabricators and engineers, it became clear—no one had an end-to-end view of the production process. The production workflow had been built in isolation, without scalability in mind.

“Within weeks of going live, this advanced circuit board fabrication facility became the bottleneck in a $1 million-per-day program.”

How I Helped:

Ask the Expert – Let’s Talk About What’s Holding You Back

Client Engagements & Industry Expertise

Real-World Business Challenges

Over the course of my career, I’ve worked with Fortune 500 companies, government agencies, and private enterprises, teaching their teams how to eliminate inefficiencies, improve workflows, and scale business operations – more than 300 clients to date. While every industry has its own nuances, the challenges they face are strikingly similar—bottlenecks, misalignment, and wasted resources that hinder growth and profitability. Here’s a look at some of the most critical business problems I’ve helped client teams solve across multiple industries.

High-Tech Manufacturing: Scaling for Production Without Failure

One of my earliest and most critical engagements was with a Top Secret, Department of Defense

project transitioning from prototype to full-scale production.

The problem? It was doomed to fail.

After speaking with the fabricators and engineers, it became clear—no one had an end-to-end view of the production process. The production workflow had been built in isolation, without scalability in mind.

“Within weeks of going live, this advanced circuit board fabrication facility became the bottleneck in a $1 million-per-day program.”

How I Helped:

Ask the Expert – Let’s Talk About What’s Holding You Back

Healthcare: Breaking Down ‘Islands of Care’

Hospitals and medical centers operate in highly fragmented systems—patients don’t just move through one linear process; they navigate disconnected ‘islands of care.’

The problem? A lack of integration across workflows.

This led to:

How I Helped:

Healthcare: Breaking Down ‘Islands of Care’

Hospitals and medical centers operate in highly fragmented systems—patients don’t just move through one linear process; they navigate disconnected ‘islands of care.’

The problem? A lack of integration across workflows.

This led to:

How I Helped:

Retail & Financial Institutions: Breaking Down Operational Silos

Retail stores, restaurants, banks, and financial service companies often operate within fragmented systems. Whether it’s managing inventory, processing transactions, or coordinating services, these organizations frequently face disconnected processes that hinder seamless customer experiences.

Retail & Financial Institutions: Breaking Down Operational Silos

Retail stores, restaurants, banks, and financial service companies often operate within fragmented systems. Whether it’s managing inventory, processing transactions, or coordinating services, these organizations frequently face disconnected processes that hinder seamless customer experiences.

Aerospace & Defense: Improving Production &

Maintenance Cycles

Maintenance Cycles

In fighter jet production, depot-level repairs, and diesel engine rebuilds, precision and efficiency are mission-critical.

The problem? Slow turnaround times and hidden inefficiencies

These organizations struggled with:

How I Helped:

Aerospace & Defense: Improving Production &

Maintenance Cycles

Maintenance Cycles

In fighter jet production, depot-level repairs, and diesel engine rebuilds, precision and efficiency are mission-critical.

The problem? Slow turnaround times and hidden inefficiencies

These organizations struggled with:

How I Helped:

Automotive & Truck Manufacturing: Scaling

Efficiency on the Assembly Line

Efficiency on the Assembly Line

In automotive and truck manufacturing, every inefficiency delays production and increases costs.

The problem? Assembly and paint lines weren’t optimized.

Companies needed to:

How I Helped:

Automotive & Truck Manufacturing: Scaling

Efficiency on the Assembly Line

Efficiency on the Assembly Line

In automotive and truck manufacturing, every inefficiency delays production and increases costs.

The problem? Assembly and paint lines weren’t optimized.

Companies needed to:

How I Helped:

Aviation & Logistics: Reducing Gate Congestion & Delays

For major airlines, gate congestion and arrival delays are an operational nightmare.

The problem? Poor gate sequencing led to inefficiencies.

Airlines needed a better way to:

How I Helped:

Aviation & Logistics: Reducing Gate Congestion & Delays

For major airlines, gate congestion and arrival delays are an operational nightmare.

The problem? Poor gate sequencing led to inefficiencies.

Airlines needed a better way to:

How I Helped:

Consumer Goods & Industrial Manufacturing: Capacity Planning & Scaling

From dishwashers and washing machines to paper products and industrial components, manufacturers

faced production bottlenecks due to poor capacity planning.

The problem? Unbalanced production and demand forecasting.

These companies struggled with:

How I Helped:

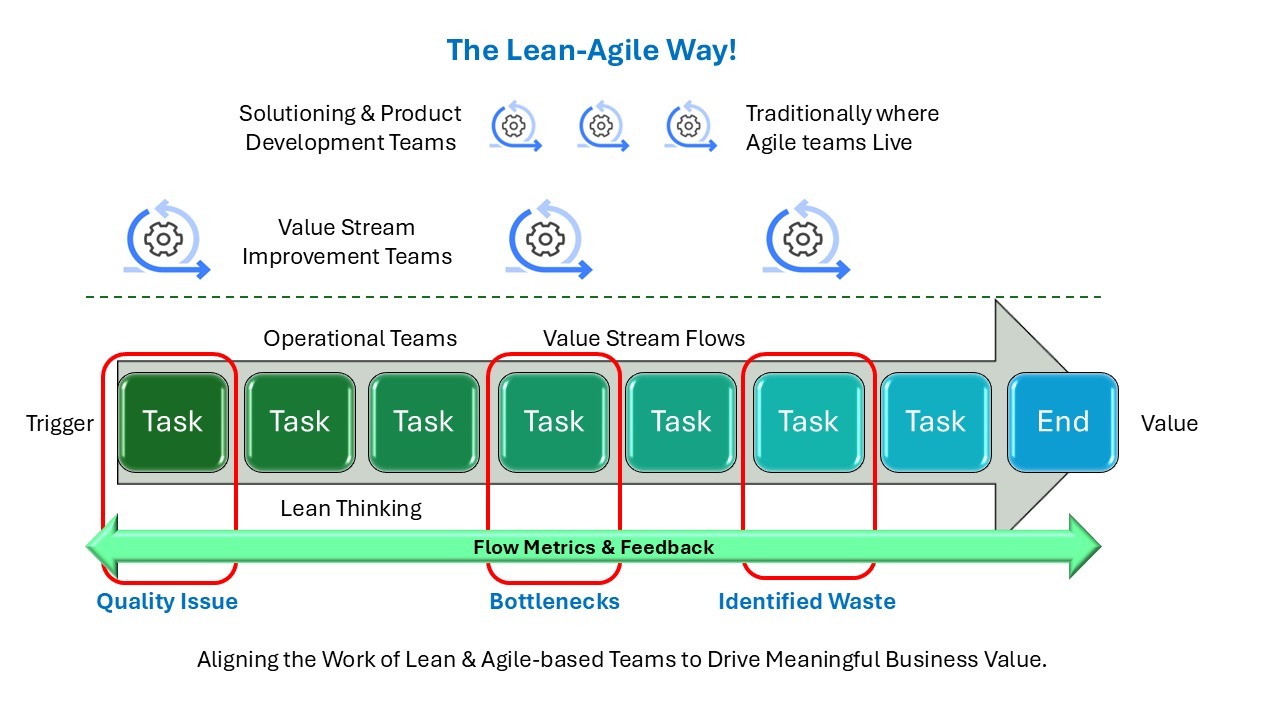

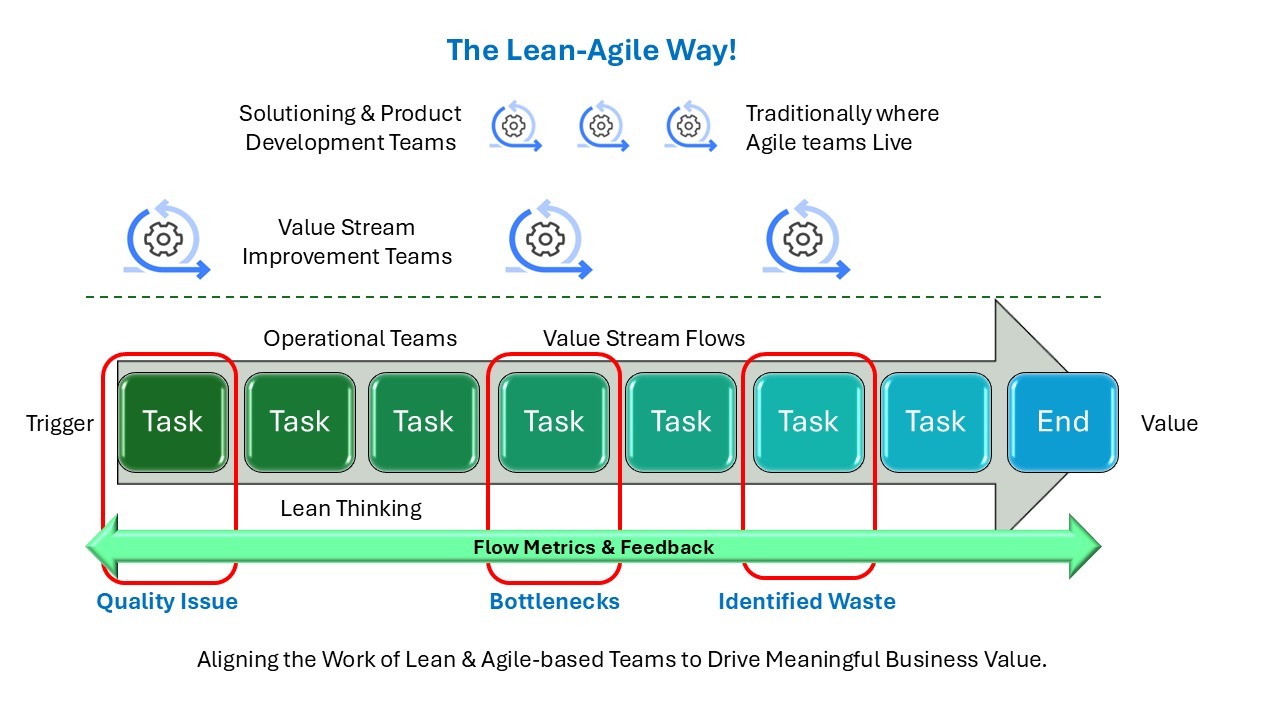

Maximizing Value Through a Holistic Approach

To deliver the most value with available time, resources, and budgets, organizations must look beyond just product features and functions. A holistic view across the value stream ensures Agile teams focus on the highest-impact areas.

Key Takeaways:

Maximizing Value Through a Holistic Approach

To deliver the most value with available time, resources, and budgets, organizations must look beyond just product features and functions. A holistic view across the value stream ensures Agile teams focus on the highest-impact areas.

Key Takeaways:

Prioritize What Matters

Prioritize What Matters

Why This Matters

Across all industries, businesses struggle with the same core challenge:

How do we maximize efficiency and deliver the most value with the time, resources, and budget available?

That’s what my Business Value Accelerator Program (BVAP) and continuing education courses are designed to solve.

Book a Free Consultation to see how BVAP can help your organization eliminate waste, scale improvements, and drive measurable business impact.

Sign Up for Online CE Courses to learn practical, real-world strategies used across multiple industries.

Why This Matters

Across all industries, businesses struggle with the same core challenge:

How do we maximize efficiency and deliver the most value with the time, resources, and budget available?

That’s what my Business Value Accelerator Program (BVAP) and continuing education courses are designed to solve.

Book a Free Consultation to see how BVAP can help your organization eliminate waste, scale improvements, and drive measurable business impact.

Sign Up for Online CE Courses to learn practical, real-world strategies used across multiple industries.

Online Continuing Education (CE) Courses

Practical, No-Nonsense Training for Certified Professionals

Are you a certified Project Management Professional (PMP), Agile-Scrum practitioner, or SAFe consultant looking for high-impact, continuing education courses?

Continuing Education That Delivers Real Value—Not Just Hours

Our online courses focus on The Lean-Agile Way’s seven core methods, providing practical solutions to real business challenges.

Online Continuing Education (CE) Courses

Practical, No-Nonsense Training for Certified Professionals

Are you a certified Project Management Professional (PMP), Agile-Scrum practitioner, or SAFe consultant looking for high-impact, continuing education courses?

Continuing Education That Delivers Real Value—Not Just Hours

Our online courses focus on The Lean-Agile Way’s seven core methods, providing practical solutions to real business challenges.

The Seven Methods of the Lean-Agile Way

The Lean-Agile Way is a practical, results-driven approach that integrates seven core methods to eliminate inefficiencies, enhance collaboration, and maximize business value. Unlike bloated frameworks that overcomplicate improvement efforts, these methods provide streamlined, scalable, and cost-effective solutions for real-world business challenges.

1. Lean-Agile Practices

2. Value Stream Management (VSM)

3. Value Stream Mapping

4. Value Stream Networks

5. BLAST (Basic Lean-Agile Solutions Teams)

6. BASE (BLAST Architecture for Strategic Execution)

7. A (Business Role Intelligence Analysis)

Have a Question on Lean-Agile Practices? Get a Straight Answer—No Buzzwords, Just Insight

The Seven Methods of the Lean-Agile Way

The Lean-Agile Way is a practical, results-driven approach that integrates seven core methods to eliminate inefficiencies, enhance collaboration, and maximize business value. Unlike bloated frameworks that overcomplicate improvement efforts, these methods provide streamlined, scalable, and cost-effective solutions for real-world business challenges.

1. Lean-Agile Practices

2. Value Stream Management (VSM)

3. Value Stream Mapping

4. Value Stream Networks

5. BLAST (Basic Lean-Agile Solutions Teams)

6. BASE (BLAST Architecture for Strategic Execution)

7. A (Business Role Intelligence Analysis)

Have a Question on Lean-Agile Practices? Get a Straight Answer—No Buzzwords, Just Insight

Why These Seven Methods Matter

Each method directly addresses specific business challenges, providing proven solutions to:

Take the Next Step—Learn & Apply These Methods Today!

Enroll in Online CE Courses to gain in-depth knowledge of these methods.

Book a Free Consultation to schedule facilitated team-based training across your

Why These Seven Methods Matter

Each method directly addresses specific business challenges, providing proven solutions to:

Take the Next Step—Learn & Apply These Methods Today!

Enroll in Online CE Courses to gain in-depth knowledge of these methods.

Book a Free Consultation to schedule facilitated team-based training across your

Business Value Accelerator Program (BVAP)

Turning Strategy into Action

The Business Value Accelerator Program (BVAP) is a structured, hands-on planning methodology that leverages the seven methods of The Lean-Agile Way to create a prioritized, actionable plan for business improvement. Unlike generic frameworks, BVAP focuses on execution—helping teams identify and implement the most impactful improvements that drive customer value at the lowest practical cost within the time, resources, and funding available.

By integrating Lean-Agile Practices, Value Stream Management, and Data-Driven Decision Making, BVAP ensures organizations can:

Whether through a focused four-hour training or a deep-dive 40-hour engagement, BVAP helps organizations move from planning to execution—faster and smarter.

Book a Free Consultation to see how BVAP can transform your business.

Business Value Accelerator Program (BVAP)

Turning Strategy into Action

The Business Value Accelerator Program (BVAP) is a structured, hands-on planning methodology that leverages the seven methods of The Lean-Agile Way to create a prioritized, actionable plan for business improvement. Unlike generic frameworks, BVAP focuses on execution—helping teams identify and implement the most impactful improvements that drive customer value at the lowest practical cost within the time, resources, and funding available.

By integrating Lean-Agile Practices, Value Stream Management, and Data-Driven Decision Making, BVAP ensures organizations can:

Whether through a focused four-hour training or a deep-dive 40-hour engagement, BVAP helps organizations move from planning to execution—faster and smarter.

Book a Free Consultation to see how BVAP can transform your business.

Mini Courses

Mini Courses

Take your career to the next level—start learning today!

Take your career to the next level—start learning today!